SOLAR Off grid Electrics in TUFF+ house kits

Overview and architecture

Direct-DC house (minimal AC conversion): DC from panels/battery is distributed to DC-native loads (LED lighting, DC-DC appliances, electronics via built-in DC supplies). Very high efficiency for those loads; requires designing or replacing many household devices for DC compatibility.

DC microgrid with local AC conversion: PV → MPPT charge controller → DC battery bus (typically 48 V or higher) → inverter(s) required only where AC is needed.

DC is most common in off-grid and hybrid systems; reduces inverter runtime, improving efficiency and reliability.

Full AC house with PV/inverter: PV → inverter → house AC panel; conventional, easiest to integrate with existing appliances and grid, but incurs conversion losses.

Null

Key components for a DC-based house

PV array with MPPT charge controllers sized to house load and location.

Battery bank designed for DC-bus voltage (24 V, 48 V, 120 V DC, or higher). Lithium batteries recommended for energy density and cycle life.

DC distribution bus and breaker panel: DC-rated wires, connectors, fuses, breakers, and isolation switches. DC circuit protection must be rated for continuous DC arcs.

DC-DC converters to provide standard voltages for devices (5 V, 12 V, 24 V, 48 V, 54 V, 120 V DC) as needed.

Inverter(s) only if AC appliances or grid export/import are required.

Monitoring, grounding, surge protection, and safety devices designed for DC systems.

DC-native appliances or retrofits: DC LED lighting, air-source heat pumps with DC compressors, DC refrigerators, DC HVAC controllers, DC EV chargers (or AC charger with inverter).

Efficiency, cost, and practicality

-

Efficiency: Every AC/DC or DC/AC conversion adds loss. Eliminating unnecessary inverters and rectifiers improves system efficiency.

Cost and availability: DC-native household appliances are now available via the RV supply market. Battery and DC distribution costs vs. savings from reduced inverter hours should be evaluated.

Maintenance: DC systems require technicians familiar with DC safety and battery care.

SOLAR DC Summary

-

Running a house largely on SOLAR PV-generated DC is technically supportable and more efficient for DC-native loads, by selecting appropriate DC voltages, using DC-rated protection, and using DC built appliances.

A practical alternative for those who want standard 110V or 240V power is a DC battery bus with selective DC distribution plus an inverter for remaining AC loads;

Full DC-native houses are best in new-build scenarios where appliance choices and safety are planned from the start. That is what TUFF+ Houses supply.

More about SOLAR...

null

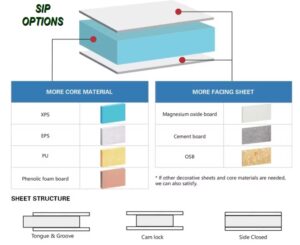

A SIP is a prefabricated building panel consisting of an insulative core sandwiched between two structural facings, used for walls, roofs, and floors, offering a strong, energy-efficient, and cost-effective construction system that does not require wooden studs.

-

Construction:SIPs are manufactured in a factory, ensuring quality control and precision, and then transported to the construction site for assembly.

The structural facings used by TUFF+ are normally MgO (Magnesium Oxide) boards, which have a long history and are explained below.

SIP Interior insulation can be a wide range of rigid insulative foams or materials including:

- Polyisocyanurate (polyiso) is a rigid, closed-cell foam insulation widely used in commercial and residential building construction, known for its high thermal efficiency, fire resistance, and moisture resistance.

- PU – Polyurethane

- Rockwool insulation, also known as stone wool or mineral wool, is a type of thermal insulation made from molten rock and recycled slag, offering excellent fire resistance, sound absorption, and durability.

- XPS insulation, or extruded polystyrene, is a rigid, closed-cell foam insulation material

- EPS or extruded Polystyrene is very commonly used as SIP insulation

SIP panels are pre-fabricated in a high tech

factory and shipped to the construction site, where they can be quickly assembled to form a tight, energy-efficient building envelope.

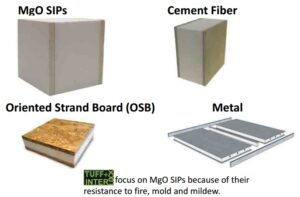

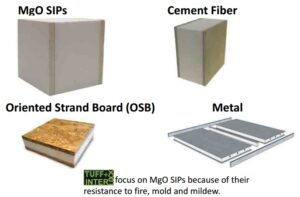

There are now many types of SIP – TUFF+ focuses on MgO structural sides because of their strength and benefits.

Practical implementation steps (Technical)

Audit loads: list appliances, power ratings, duty cycles; separate DC-friendly vs AC-only loads.

Choose DC-bus voltage that minimizes current while remaining safe and supported by equipment (48 V is a common starting point).

Size PV array and battery capacity to meet energy and autonomy goals.

Design DC distribution with DC-rated breakers, wiring, and surge protection.

Select DC-native appliances where cost-effective; use high-efficiency inverters only for unavoidable AC loads.

Install per local code with licensed professionals; include monitoring and maintenance plan.

Typical use cases

Off-grid homes: DC battery bus with inverter backup is common to minimize inverter runtime and maximize efficiency.

Net-zero or grid-tied homes: PV with inverter, battery backup, and selective DC distribution for critical loads (lighting, comms, pumps).

Tiny homes, RVs, boats: often run primarily on DC (12–48 V) because loads are smaller and designed for DC.

Remote telecom/industrial sites: use high-voltage DC buses routinely for efficiency.

Appliance compatibility and retrofitting

Electronics and LED lighting often accept DC internally; many devices such as phones and computers already use DC internally after AC-DC conversion.

Resistive loads (electric water heaters, ovens) work on DC but require DC-rated controls.

Motors and compressors: most AC motors need inverters; modern HVAC and refrigeration increasingly use brushless DC motors that can run efficiently on DC via appropriate drives.

Cooking, clothes dryers, and most major appliances are now available in DC – exceptions are more challenging to convert; often easier to keep them AC and use a small inverter or hybrid approach where necessary.

DC Safety and Implications

null

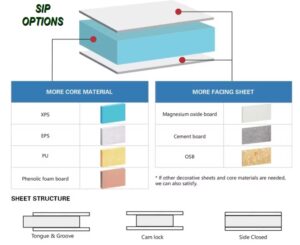

A SIP is a prefabricated building panel consisting of an insulative core sandwiched between two structural facings, used for walls, roofs, and floors, offering a strong, energy-efficient, and cost-effective construction system that does not require wooden studs.

-

Construction:SIPs are manufactured in a factory, ensuring quality control and precision, and then transported to the construction site for assembly.

The structural facings used by TUFF+ are normally MgO (Magnesium Oxide) boards, which have a long history and are explained below.

SIP Interior insulation can be a wide range of rigid insulative foams or materials including:

- Polyisocyanurate (polyiso) is a rigid, closed-cell foam insulation widely used in commercial and residential building construction, known for its high thermal efficiency, fire resistance, and moisture resistance.

- PU – Polyurethane

- Rockwool insulation, also known as stone wool or mineral wool, is a type of thermal insulation made from molten rock and recycled slag, offering excellent fire resistance, sound absorption, and durability.

- XPS insulation, or extruded polystyrene, is a rigid, closed-cell foam insulation material

- EPS or extruded Polystyrene is very commonly used as SIP insulation

SIP panels are pre-fabricated in a high tech

factory and shipped to the construction site, where they can be quickly assembled to form a tight, energy-efficient building envelope.

There are now many types of SIP – TUFF+ focuses on MgO structural sides because of their strength and benefits.

Key components for a DC-based house

PV array with MPPT charge controllers sized to house load and location.

Battery bank designed for DC-bus voltage (24 V, 48 V, 120 V DC, or higher). Lithium batteries recommended for energy density and cycle life.

DC distribution bus and breaker panel: DC-rated wires, connectors, fuses, breakers, and isolation switches. DC circuit protection must be rated for continuous DC arcs.

DC-DC converters to provide standard voltages for devices (5 V, 12 V, 24 V, 48 V, 54 V, 120 V DC) as needed.

Inverter(s) only if AC appliances or grid export/import are required.

Monitoring, grounding, surge protection, and safety devices designed for DC systems.

DC-native appliances or retrofits: DC LED lighting, air-source heat pumps with DC compressors, DC refrigerators, DC HVAC controllers, DC EV chargers (or AC charger with inverter).

Building Safety and code

DC behaves differently from AC: arcs are harder to quench, polarity needs careful management, and equipment must be DC-rated.

Electrical codes: NEC (US) and national/local codes regulate installation, battery storage, inverter interconnection, and DC bus implementations. Some jurisdictions require licensed electricians and inspections.

Isolation and emergency disconnects are mandatory. Firefighting and first-responder considerations must be addressed.

DC Voltage choices and implications

Low-voltage DC (12 V, 24 V): easy for small loads, high currents for household power — large copper conductors, higher losses; better for lighting, small appliances.

Medium-voltage DC (48–60 V): common compromise — safer (below extra-low/high risk thresholds varies by jurisdiction), lower current, common battery standard.

TUFF+ does not use High-voltage DC (120–400 V+): reduced currents and conductor size, which requires stricter insulation, safety, and DC-rated equipment; 120–380 VDC bus is used in advanced microgrids and telecom/industry.

Efficiency, cost, and practicality

RUNNING COSTS are low and can be ZERO!

If used in a tropical or sunny climate, the electricity generated and stored in a TUFF+ house battery block can be sufficient to run lights, appliances and air-conditioning all day and night.

TUFF+ converts the excess heat into cooling and running the house.

NOTE Efficiency: Every AC/DC or DC/AC conversion adds loss. Eliminating unnecessary inverters and rectifiers improves system efficiency. TUFF+ takes direct SOLAR DC electrical supply and using it without inefficient conversion.

Cost and availability: DC-native household appliances are now available via the RV supply market. Battery and DC distribution costs vs. savings from reduced inverter hours should be evaluated.

Maintenance: DC systems require technicians familiar with DC safety and battery care.