PRODUCTS

PRODUCTS

TUFF+ Product Catalog by Sector

TUFF+ innovative product made from metalized polymers using cutting edge technology. Our Recycled TUFF+ Sheet is a stronger and water & insect proof substitute for PLYWOOD, MDF, PVC and WPC sheet.

Material : Aluminum/PP/HDPE/ABS/HIPS/PVC/WPC/PC composite

thickness: 0.5 mm to 100 mm

size : 1220 mm X 2440 mm / above 10 mm 1000 mm X 2000/3000/4000/5000 mm

Our Recycled metalized Sheets are high strength with properties such as resistance to water, termite proof and heat resistance, thus making it an ideal weatherproof choice for various applications.

Composite solid 8x4' panels

Description:

TUFF+ range of application based low maintenance decking is suitable for every need.

Elegant colours, combined with different surface finishes, results in an unmatched choice for different conditions that look great and will stay that way.

High performance, low on maintenance, Shubhwood reversible deck planks are fitted to an aluminium framework with concealed fixtures, offering barefoot safe anti-skid surfaces.

SPECIFICATIONS:

Profile Code: SW-1001

Dimension : 145mm x 23mm

Standard Length: 2.44 mts / 8'

Standard color: Wenge, Walnut

Special Colors: Red, Black, Yellow, Beach White

Surface Finishes: Sanding, Brushing

SPECIFICATION:

- Profile Code: SW-2001-2-3-4 and 5

- Dimension : 300mm x 300mm

- Standard Thickness: 20mm

- Standard Colors: Wenge, Walnut.

- Special Colors: Red, Black, Teak, Beach White.

- Surface Finishes: Brushing.

WPC deck tiles in varied shades and grain textures. Our flooring solutions are convenient, elegant, low maintenance, eco-friendly, and good for any budget! Whether it’s by the pool or the porch, we have the wooden deck flooring you are looking for. Stylish and practical, our flooring solution will last you a lifetime.

SPECIFICATION:

- Profile Code : SW-1005(H)

- Dimension : 145mm x 21mm

- Standard Length: 2.44 mts / 8'

- Special Colors: Teak Wood, IPE Wood, Maple Wood, Grey

- Surface Finishes: Brushing

BENEFITS OF WPC (Wood Polymer Composite)

Water Resistant, Eco Friendly, Low Maintenance, Easy Installation, Non-Flammable, Resistance to microbial or insect infestation, Durable.

Structural beams for joists or rafters. FRP composites offer an optimal strength-to-weight ratio alongside superior durability, corrosion resistance and affordability.

Strong as steel and able to be installed without a crane in most circumstances

No rust

Composite material made from Poltruded glass, 5 km rolls of glass wire are pulled through each beam

(Note not small fibers of glass as used in fiberglass)

Also available in other profiles such as wall studs

Typical applications include: supporting structures, platforms, roof or floor support, stairways, walkways, sewage plants, or bridges.

What is FRP?

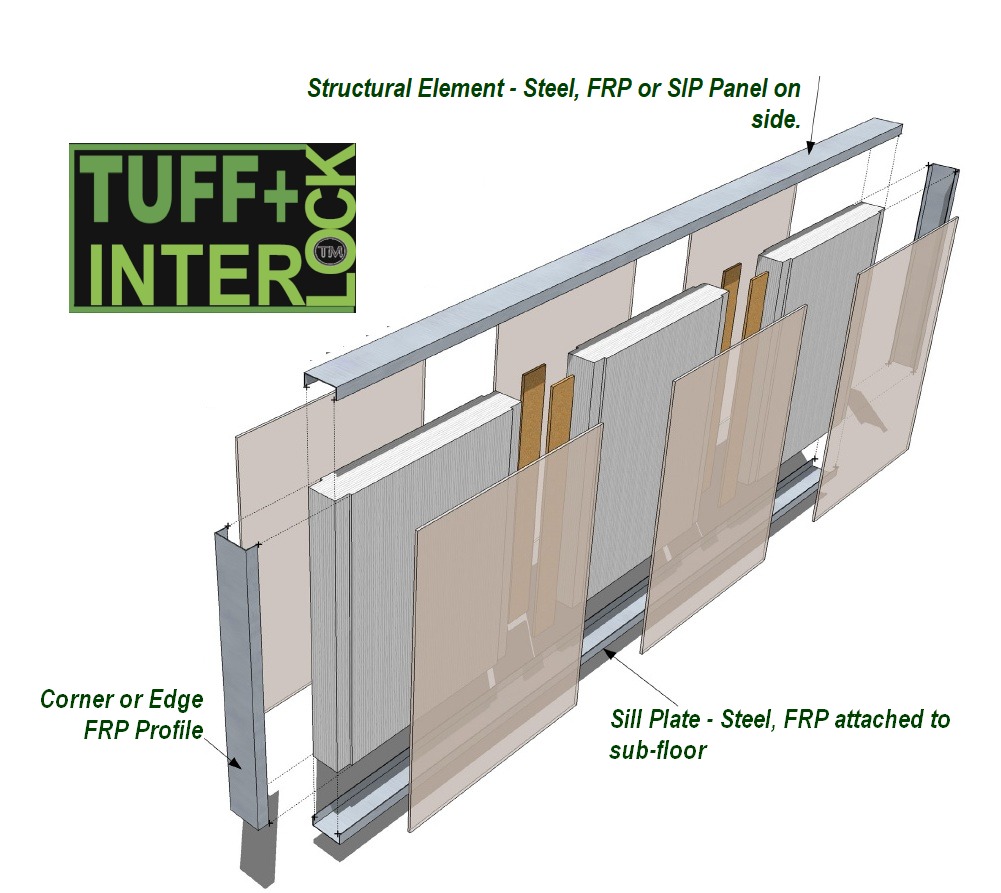

Fiber reinforced panels or fiber reinforced polymers more commonly abbreviated and known as FRP is a composite material comprised of carbon fiber reinforced polymers (CFRP). Traditionally, FRP has been utilized for decades within the civil, aerospace, and automotive industries for applications requiring high strength-to-weight ratios and rigidity.

FRP has crossed over into the construction industry in the form of fiber reinforced panels (FRP) beam profiles, studs, ceiling and wall panels.

This lightweight and durable material is unlike traditional building materials in that it provides the perfect balance between cost-effectiveness, durability, and customization.

The benefits of FRP within the construction industry include:

- Strength and durability – Very high strength & resists impacts and scratches externally

- Easy to work with, can be drilled, cut, screwed etc with normal woodworking tools

- Lightweight – I-beams or panels can easily be carried by one person and installed within minutes using fasteners

- Low maintenance

- Cost-effective – shipping and labor costs are greatly reduced

- Range of unique surface types, colors and textures – provides unique and customizable solutions for any project

- Water and mold proof– won’t weaken over time and non-porous surface

Wood rots. Steel rusts. FRP lasts.

Traditional building materials have their place. But for harsh, corrosive environments, Bedford fiber-composite reinforced polymer (FRP) is a smart choice.

Structural FRP has the strength of steel at a fraction of the weight. It won't corrode, rot, is imperious to insect damage nor will it conduct electricity. It can be formed into countless FRP profiles to fit your requirements. And decades later when those other materials need to be replaced, it will still have plenty of life.

In short, fiberglass pultrusions give you a different way to solve your construction challenges — one that can reduce costs and improve performance in the long run. It is best to work with the properties of fiberglass reinforced plastic from the start of your construction project.

FRP Grids that support people or animals walking on it.

Suitable for factory walkways, chicken farms etc

Features of Pultruded Fiberglass Grating

- Corrosion Resistant

- Extremely Strong

- Impact Resistant

- Non-Skid Surface / Anti-Skid

- Low Electrical and Thermal Conductivity

- Easily Fabricated in the Field

Color, transparent etc

What is FRP? Link to see article

1. FRP Roofing Sheets Are Anti-Corrosive and Anti-Rust

One of the clearest advantages of FRP roofing sheets is their anti-corrosion and anti-rust properties. They are known for their durability. Fiber-reinforced polymers and plastics can be made with various composite materials to get the exact properties needed for a specific project.

The result is frequently a roofing material that can withstand the elements and moisture exposure at a very high standard. This is important to note in construction because corrosion can be highly dangerous for a building’s structural integrity and safety, particularly when it comes to the roof. However, corrosion and rust are not a concern with FRP roofing sheets.

FRP roofing sheets are also great for projects that don’t face particularly hostile conditions, such as residential housing. Their anti-corrosion and anti-rust properties allow them to last longer than other materials. This is especially important in commercial construction, which often involves large structures that need to last decades without losing their external aesthetics to the elements.

2. FRP Roofing Sheets Are Simple and Cost-Effective

Another great advantage of FRP roofing sheets is their easy and affordable installation. In the modern construction industry, projects are consistently on tight timelines with little room for delays. Construction teams can deliver rapid turnaround with FRP roofing sheets. They are lightweight, and workers can attach tools like attachment points and nonslip covers to make installing them even easier.

Plus, once the panels are installed, their durability will allow them to last years before needing to be replaced. Project managers and stakeholders can save money and get a faster completion time on their projects by opting for FRP roofing sheets as opposed to other materials. That makes this choice an economical option for many builders on a budget and tight timeline.

3. FRP Roofing Sheets Are Sustainable and Durable

Sustainability has become a top priority for businesses and consumers over recent years. Construction companies can contribute to the sustainable building movement by using FRP roofing sheets. They can choose a composite that is made with more environmentally friendly components.

Additionally, choosing FRP roofing sheets reduces waste due to the longevity of the panels. An FRP roof will last longer than many other alternatives, such as conventional shingles. Plus, when it is time to replace the roof, these sheets can simply be recycled. They do not need to go to a landfill like other materials would.

Even the anti-corrosive properties of FRP roofing sheets contribute to their sustainability. Since these panels do not rust or corrode, rainwater runoff from the roof won’t contain toxins from corroding metal, reducing pollution seeping into surrounding soil and waterways. This protects the health of building residents and is also good for the planet.

4. FRP Roofing Sheets Offer a Wide Variety of Colors and Styles

Choosing a sustainable and durable roofing material doesn’t mean sacrificing style and customization. Construction companies can get their clients the perfect type of roof using FRP roofing sheets. They’re available in various colors and aesthetics. Creating different shapes and designs is easy with FRP sheets, as well. Their unique properties can even be customized by tweaking the composites they’re made from.

These characteristics mean FRP roofing sheets can be used on various projects with many architectural styles. These panels can be used for all types of buildings, from urban office spaces to corporate retreats in the mountains. The level of customization allows them to be adapted to virtually any aesthetic.

5. FRP Roofing Sheets Are Great for Prefab Construction

Prefabricated construction is considered by many to be the future of the building industry, along with 3D printing. Prefab and modular construction prioritize affordability and efficiency in the building process. Easily compatible mass-produced components allow entire buildings to be produced rapidly.

FRP roofing sheets are the perfect roofing option for prefab and modular construction. It’s easy and quick to install, which is right in line with the efficient construction process needed on these projects. Plus, FRP sheets go well with various building styles, so a company could use several kinds on different projects. The durability and longevity of FRP roofing contribute to the cost-effectiveness of prefab and modular construction, as well.

6. FRP Roofing Sheets Are Easy to Maintain

FRP roofing sheets are highly convenient and easy to maintain after installation. Water damage is extremely unlikely, thanks to their anti-corrosion and anti-rust properties. This makes annual maintenance for commercial buildings with FRP roofing simple and straightforward, cutting back on the time needed for regular upkeep.

Buildings with FRP roofing sheets will have fewer water leaks, a stronger building envelope and better drainage during wet seasons. This results in better durability for an entire building. The system securely keeps water off the building, so it is less likely to seep in at the edges of walls, windows and doors. A strong, water-resistant roof made with FRP sheets can help prevent moisture damage throughout a building from the top down.

7 Durability and Style With FRP Roofing Sheets

FRP roofing sheets are the perfect material for all sorts of buildings. It’s hard to go wrong with FRP roofing when it comes to commercial construction, thanks to its durability and customization features. Installation is quick and easy, making for a fast and affordable process. This option results in safe and weather-resistant buildings with great style and aesthetics.

Insulated metal panels, or IMPs, are known for their exceptional thermal insulation properties.

These panels or planks consist of a metal face with a foam insulation core with an optional metal backing.

IMPs offer energy efficiency and structural stability, making them ideal for applications where insulation is paramount, such as cold storage facilities or energy-efficient buildings.

Thickness : 2.00mm to 18.00 mm

GSM : 250 to 6000

width : 1600 mm max X length as per needed

colors : White, Black, Gray, Blue Standards, for bulk quantity as per Pantone color chart

Grade : UV stabilized, FR, ESD, Corona treated

Surface: plain, glossy, textured, Matt finished,

Lamination : non-woven fabric, any pp-based filmXLPE, etc etc

Applications: constructions, formwork panels, packaging, kit home building, printing, layer pads, flight cases, and many more....

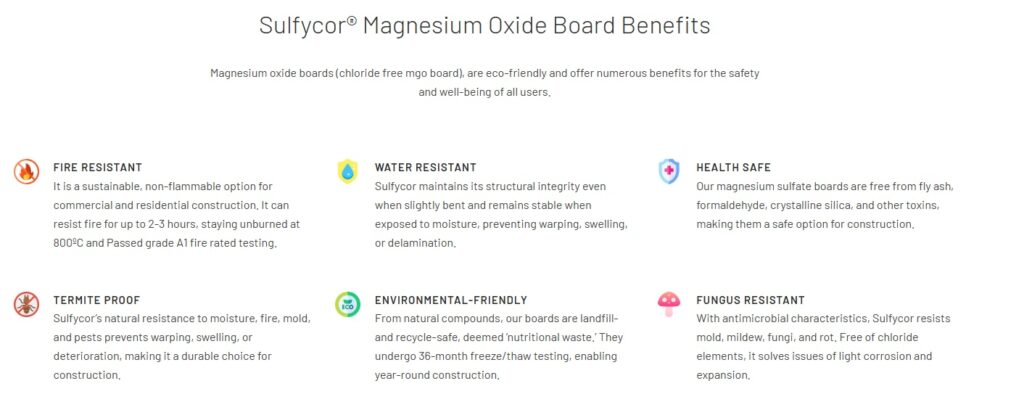

MgO board, also known as magnesium oxide board, is a building material made from magnesium oxide, a mineral cement, and reinforced with fiberglass mesh, offering fire resistance, water resistance, and durability

The best facing for Structural Insulated Panels (SIP) because of benefits.

SEE ALSO:

https://tuffplus.global/announcements/sip/

MgO has superior fire suppression characteristics when compared to portland cement, OSB, and plywood. MgO's water-resistant characteristics make it more resistant to mold than plywood, OSB, and gypsum board. MgO SIPs provide numerous health and safety benefits to homeowners.

MgO itself is resistant to fire and mold and won’t off-gas harmful fumes.

Thick MgO SIPs provide superior comfort and efficiency without the need for additional insulation or air barrier. Homeowners concerned for their carbon footprint will like that SIP home construction drastically reduces construction waste, and reduces carbon emissions from transportation to and from the building site.

MgO SIPs are used in walls, ceilings, roofs, decks, and foundations. Different SIP configurations are suitable for different conditions

Magnesium Oxide Boards vs. Other Materials

It’s safe to say that magnesium oxide boards have several advantages over other construction materials, based on the benefits previously mentioned.

a. Gypsum

Although both gypsum and magnesium oxide boards are eco-friendly, the former poses more harm to people because its fly ash releases toxins when cut.

b. Portland cement

Portland cement lacks water-resistant and fire-suppressing capabilities. Plus, MgO leaves a smaller carbon footprint compared to cement. And although Portland cement is recognizably strong, MgO has a higher rating on impact strength even though it is considerably lighter in weight.

c. Plywood

MgO is undoubtedly safer than plywood as a construction material. Plywood is not flame resistant and could quickly spread fire it is not water resistant, making it susceptible to moisture that could grow mould and vulnerable to water damage.

d. Oriented strand board (OSB) - a wood fiber board similar to plywood.

When it comes to safety, MgO ranks higher than OSB. The OSB releases formaldehyde, a dangerous toxin. It is not fire resistant nor is it resistant to moisture and termites.

What is the composition of a MgO?

Magnesium oxide board is made of natural materials such as inorganic substances, plant fibres. It is eco-friendly, healthy, and pollution-free, with no asbestos, formaldehyde and radiation.

Magnesium oxide is a natural non-toxic inorganic mineral. It is calcined and pulverized into powders and mixed in the magnesium chloride solution.

Magnesium chloride (MgCl2) is added to the magnesium oxide powder to create an aqueous solution. It is stirred until it becomes cement slurry.

Perlite (PO4) is a type of obsidian, which is a vitric rock cooled rapidly from lava in volcanic eruption. It is widely used as an insulating material and added to magnesium oxide boards to enhance its fire resistance.

Wood fiber, also known as sawdust, is mixed into the cement slurry and acts as an adhesive to assist the overall performance of the product.

Non-woven fabric is composed of directional or random fibres, with moisture-proof, breathable, flexible and other characteristics.

Fiberglass mesh is an inorganic non-metallic material with excellent performance, which increases the strength and toughness in the board.

DESCRIPTION:

TUFF+ hollow profiles are the perfect material for pergolas, WPC Gazebo, and Wooden Gazebo elevation features. Our lightweight sections replace heavy steel frames or wood which demand periodic maintenance and painting to avoid deterioration from exposure to weather or corrosion.

With a wood appearance that requires little maintenance, Tuff+ profiles retain natural wood aesthetics in terrace and Wooden pergolas, garden pergolas, cantilever features, car parks, elevation features of buildings, and other applications.

Example Products

HOW TO USE THIS PRODUCT CATALOG

1 Select the Category/Sector which you wish to search in.

2 Enter a word or keywords or a phrase into the “Product Search” field

3 Matches will be shown listed below, and you can then click on any match to see the details of that product.

4 To start a new search, click the RESTART button

Discover TUFF+ products

You can also search by any keyword using the global search menu option!

Photos of TUFF+ Manufacturing Plants