Structural Insulated Panels (SIP)

What are they, SIP history, and SIP use in building today!

What is a Structural Insulated Panel or 'SIP'

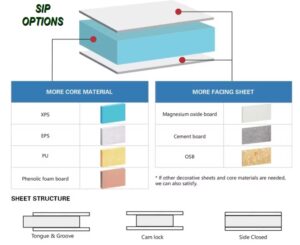

A SIP is a prefabricated building panel consisting of an insulative core sandwiched between two structural facings, used for walls, roofs, and floors, offering a strong, energy-efficient, and cost-effective construction system that does not require wooden studs.

-

Construction:SIPs are manufactured in a factory, ensuring quality control and precision, and then transported to the construction site for assembly.

The structural facings used by TUFF+ are normally MgO (Magnesium Oxide) boards, which have a long history and are explained below.

SIP Interior insulation can be a wide range of rigid insulative foams or materials including:

- Polyisocyanurate (polyiso) is a rigid, closed-cell foam insulation widely used in commercial and residential building construction, known for its high thermal efficiency, fire resistance, and moisture resistance.

- PU – Polyurethane

- Rockwool insulation, also known as stone wool or mineral wool, is a type of thermal insulation made from molten rock and recycled slag, offering excellent fire resistance, sound absorption, and durability.

- XPS insulation, or extruded polystyrene, is a rigid, closed-cell foam insulation material

- EPS or extruded Polystyrene is very commonly used as SIP insulation

SIP panels are pre-fabricated in a high tech

factory and shipped to the construction site, where they can be quickly assembled to form a tight, energy-efficient building envelope.

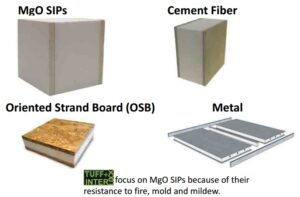

There are now many types of SIP – TUFF+ focuses on MgO structural sides because of their strength and benefits.

Advantages of Structural Insulated Panel or 'SIP'

SIPs are prefabricated systems used primarily for walls and roofs.

SIPs employ composite materials, reduce waste through modular construction methods, achieve high insulation values, and may be used instead of many conventional building methods. It can be used in construction as a fireproof wall and a TUFF+ SIP module can be installed by two workers:

- Speed of implementation – in accordance with the principle of “time is money”, using SIPs is a modern method of erecting buildings, reducing costs and limiting the duration of the construction process.

- Extended construction season – because there is no need for cement and plasters, construction in winter is possible

- More usable area – thinner walls and better thermal parameters allow for up to 10% more usable area compared to traditional materials

- Energy efficiency – lower building operating costs by approx. 40% compared to a traditional building

- Fire safety – greater fire safety of the building structure compared to traditional frame construction

- Tightness of structural partitions – an important element in the standard of energy-efficient and passive houses, which has a significant impact on energy consumption

- Healthy construction material – wall and structure cladding made of MgO Green boards is a barrier against the formation of mold and fungi and protects against rot and moisture

- Lower investment costs – shorter implementation time, no material losses on construction site

History of SIPs In Construction

Structural Panels were first invented in the early 1940s

Famous American architect Frank Lloyd Wright was exceptionally innovative and introduced the idea of SIPs to incorporate beauty and simplicity to build cost-effective homes.

Alden B. Dow, an architecture student of Frank LloydWright, experimented further with the concept of structural panels. He had concerns about energy efficiency and was fearful over depleting natural recourses. He sought to create a structural panel with an insulated core and is generally credited with creating the first structural insulated panel.

• The first foam core SIPs were created in 1952

- In the early 1990’s advanced computer-aided manufacturing (CAM) technology was developed

that allowed cutting machines to fabricate SIPs to match a building’s

specific design. - Since 2000, the market for SIPs has been growing, driven by increasing demand for energy-efficient and sustainable construction materials.

- There is an organization that guides SIP development in North America: https://www.sips.org/frequently-asked-questions-about-sips

- Today, SIPs offer a high-tech solution for residential and nonresidential buildings, including multistory building applications.

MgO - Magnesium Oxide Board

In the context of Structural Insulated Panels (SIPs), “MgO” refers to Magnesium Oxide board, which is a material used as SIP sheathing side layers, providing superior fire resistance, water resistance, and durability compared to traditional materials like OSB (Oriented Strand Board which is like Plywood)

Brief History of Magnesium Oxide Boards

MgO (Magnesium Oxide boards) have changed the construction sector. Even though they have been used for centuries, they are still not commonly known.

First Use of Magnesium Oxide

While Magnesium Oxide boards created in a facility are a relatively new invention, magnesium oxide itself has been used in building for centuries. It was formerly used in masonry alongside mortar. Its traces canbe seen everywhere, from the Roman Empireto the Great Pyramids. It was the main construction material used for the Great Wall of China.

Use of Magnesium Oxide has increased significantly this century in the form of MgO boards because prices have become competitive with OSB. It’s now regarded as a leading, long-lasting building material, and favoured also for flooring because of its strength.

How are MgO Boards Made?

MgO is made from oxygen and magnesium.

Whereas it could be manufactured artificially, the majority of the magnesium carbonate we consume is naturally found and is abundant in Europe and China.

It goes through a procedure in which the magnesium is combined with oxygen and then subjected to heat and pressure. Magnesium oxide is produced as a result. MgO has essentially the same characteristics as a rock after it has been heated.

MgO boards are now also available in many forms including the appearance of wood or stone:

To make Magnesium Oxide boards for building purposes, the raw material is reduced to powder and combined with water, sulfates or Epsom salts, cellulose, perlite, and other building material.

Advantages of MgO SIPs

- Strength and Durability:

MgO boards are known for their high strength and durability, exceeding that of plywood, OSB, and particleboard. - Fire Resistance:

MgO boards have excellent fire suppression characteristics, outperforming plywood and other common building materials. - Water and Mold Resistance:

MgO boards are naturally resistant to water damage and mold growth, unlike plywood which can absorb moisture and deteriorate. - Sustainability:

MgO boards are a sustainable option, as they are made from natural, mineral-based materials. - Faster Construction:

SIPs using MgO boards can be assembled faster than traditional stick-built homes, reducing construction time. - Reduced Waste:

MgO SIPs can help reduce construction waste compared to traditional methods. - Improved Insulation:

MgO SIPs are airtight and insulated, leading to better energy efficiency and reduced heating/cooling costs. - No Harmful Off-Gassing:

Unlike OSB wood composites, which may contain formaldehyde-based glues, MgO boards are free of VOCs, promoting better indoor air quality. - Versatility:

MgO boards can be used for various applications, including fascias, soffits, tile backers, wall and ceiling linings, and underlayment.

MgO board is generally considered stronger and more durable than OSB/plywood, especially in the context of Structural Insulated Panels (SIPs), offering superior fire resistance, water resistance, and longevity.