TUFF+ INTERLOCK Structural Insulated Panels (SIP)

BUILDER Load and Specification information – Confidential for franchisees and certified builders

TUFF+ INTERLOCK 'SIP' explained for builders

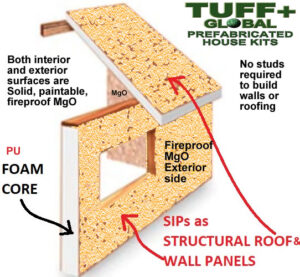

TUFF+ INTERLOCK SIP panels consisting of an insulative core sandwiched between two structural facings, used for walls, roofs, and floors, offering a strong, energy-efficient, and cost-effective construction system that does not require wooden studs.

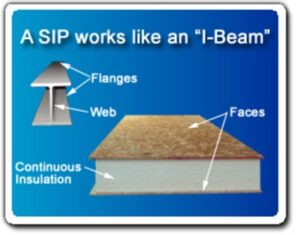

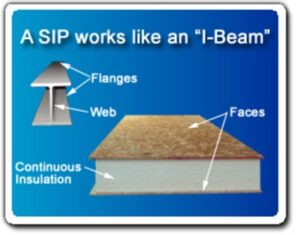

Structural insulated panels (SIPs) possess high compressive strength in walls due to their sandwich-like construction, which mimics the structure of a steel I-beam. The rigid foam core acts as the web, while the strong outer layers (often OSB) function as flanges, distributing compressive loads evenly and resisting buckling. This design, combined with the strong bond between the core and facers, results in a panel that can handle significant compressive forces.

I-beam analogy:

SIPs are engineered to behave like an I-beam. The MgO board on the exterior sides act as the flanges, resisting bending and tension, while the foam core provides support and bracing, preventing the flanges from buckling under compression.

The structural facings used by TUFF+ for walls use MgO (Magnesium Oxide) board skins which are very strong:

SIP inside insulation used:

PU foam for wall SIP

EPS foam for mini-SIP spline

EPS foam for TUFF+ BASE profile

Advantages of Structural Insulated Panel or 'SIP'

SIPs are prefabricated modular systems used primarily for walls and roofs, but also applicable to floors, and other structural areas.

SIPs employ composite materials, reduce waste through modular construction methods, achieve high insulation values, and may be used instead of many conventional building methods.

BENEFITS LIST and EXPLANATIONS

Construction Speed and Cost Savings:

- Faster Construction: SIPs are prefabricated off-site and arrive ready for installation, drastically reducing on-site construction time compared to traditional methods.

- Reduced Labor Costs: The speed of SIP construction translates to lower labor costs. TUFF+ SIPs can be joined strongly using TUFF+ CamLock technology:

- Material Efficiency: SIPs minimize material waste during construction.

Structural Strength and Durability:

-

Stronger and More Durable:

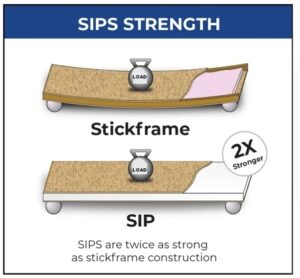

SIPs form a monolithic shell, making them significantly stronger and more durable than traditional framing.

-

Resistant to Extreme Weather:

SIPs can withstand extreme weather conditions, including hurricanes, tornadoes, and seismic activity

-

Longer Lifespan:

SIPs have a long lifespan, with buildings constructed with SIPs expected life-span 50-100 years.

Energy Efficiency:

-

Lower Heating and Cooling Costs:SIPs provide superior insulation, leading to significant savings on energy bills for heating and cooling.

-

Reduced Energy Consumption:The airtight building envelope created by SIPs minimizes air leaks, reducing the overall energy consumption of the building.

-

High R-value:SIPs offer a high R-value (a measure of thermal resistance), meaning they are excellent at resisting heat flow and keeping the building comfortable.

Environmental Benefits:

-

Reduced Waste:

SIPs minimize waste during construction, reducing the amount of material sent to landfills

-

Sustainable Materials:

SIPs are often made with sustainable materials, such as engineered wood products and recycled content, further reducing their environmental impact.

-

Reduced Carbon Footprint:The energy efficiency of SIPs contributes to lower greenhouse gas emissions and a reduced carbon footprint.

Indoor Air Quality:

-

Reduced Air Leaks:SIPs create a very airtight building envelope, minimizing drafts and the entry of outside pollutants, allergens, and moisture.

-

Controlled Ventilation:SIPs allow for controlled ventilation, which can be filtered to remove contaminants and allergens, improving indoor air quality.

-

Reduced Mold and Mildew:The airtight and moisture-proof MgO skin of SIPs prevent mold and mildew growth.

Other Benefits

- Speed of implementation – in accordance with the principle of “time is money”, using SIPs is a modern method of erecting buildings, reducing costs and limiting the duration of the construction process.

- More usable area – thinner walls and better thermal parameters allow for up to 10% more usable area compared to traditional materials

- Energy efficiency – lower building operating costs by approx. 40% compared to a traditional building

- Fire safety – TUFF+ Fireproof building structure

- Tightness of structural partitions – an important element in the standard of energy-efficient and passive houses, which has a significant impact on energy consumption

- Healthy construction material – wall and structure cladding made of MgO eco friendly boards is a barrier against the formation of mold and fungi and protects against rot and moisture

- Lower investment costs – shorter implementation time, no material losses on construction site

- Extended construction season – because there is no need for cement and plasters, construction is possible all year round

MgO can be used in construction as a fireproof wall – and is the siding material for the TUFF+ SIP wall panels.

PU which is the TUFF+ SIP CORE material complies with USA fireproof ratings.

SEE ALSO TUFF+ FRP Building benefits.

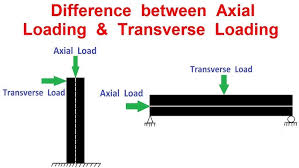

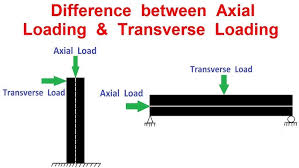

AXIAL loading on wall SIPs

SIPs are subject to two major load types, Axial and Transverse.

Axial (The pressure pressing down onto a column from the top) loading

Transverse loading (the weight of a person standing on roof beam) is explained on the next tab.

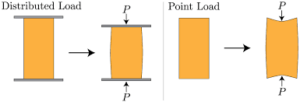

TUFF+ design caters for AXIAL loads both distributed (typically load bearing per linear foot or meter) and Point loads (typically the load where a specific beam or structural item needs to be supported)

SIPs can handle substantial vertical loads.

For example, individual TUFF+ SIP panels can support a minimum of 2500 lb per linear foot to over 4,000 lb per lineal foot. (over 2 tonnes per foot)

MgO/PU SIPs can support high AXIAL loads

TUFF+ SIP panels, measuring 100mm in thickness, 3m in height, and 0.6m in width, will support a vertical load minimum of 2500 lb 1134 kg) per linear foot using a TUFF+ mini-SIP sline .

This load bearing exceeds the the average foundation loading of a typical two-storey house constructed using traditional methods and yet TUFF+ houses are less than half a traditional house weight!

Let’s go into the calculations of why this is so.

Using wood/ concrete methods, a bungalow one story home will be around 135 lb psf, a two-story home is estimated to weigh around 275 pounds per square foot, while a three-story could be approximately 350 pounds per square foot. TUFF+ houses are a fraction of this weight.

LOAD EXAMPLE

A TUFF+ Economy 400sf single floor house will typically weigh much less than a max of 33,000 lb (including contents, snow load etc.) This is very low weight for a house.

How can we be so sure of this? Because a TUFF+ single story house kit (including all materials and fitout) of 400sf (40m2) TUFF+ House Kit is shipped in a 20′ container and the absolute load of a kit of this size can not exceed 13 tonnes.

In fact a TUFF+ 40 square meter Kit total house weight is calulated as less than 10 tonnes (22,000lb) INCLUDING the weight of the TUFF+ BASE foundation, 200 visitors having a party and a meter of snow on the roof!

TOTAL Axial load of the entire structure onto the foundation will be less than 22,000 lb which is 22,000 / 400 = 55 lb psf (268 KG/m2).

CONCLUSION #1

TUFF+ House loads are much lighter than traditional stick or concrete homes, by a factor of 55/135 = 40% of the weight of a traditional concrete or wooden house, yet stronger due to SIP design.

NOTE MgO /PU SIPs are stronger, much stronger than traditional building design, and also stronger than the OSB/EPS SIP built houses.

To carry the weight of the entire house would require no more than 22,000lb or 10 tonnes as explained above. Yet the top of every foot length of TUFF+ wall panel will support more than 2500 lb of weight! So the distributed load of the entire house can be supported by less than 9 feet of wall or 5 feet of foundation!

NOTE The exterior wall length of this size house is 80 feet, so will support a load greater than 8 times that which is required.

CONCLUSION #2

4.25″ (110mm) SIP 10′ high walls (3 meters high) will easily support a 4 story house

Shorter SIP structure has a proportionally higher load bearing.

OTHER SIP PROPERTIES

Even load distribution:

The continuous foam core distributes compressive forces across the entire panel, rather than concentrating them on a frame as in traditional stick-framing.

Bond strength:

The strong adhesive bond between the foam core and the outer layers is crucial for transferring loads effectively and ensuring the panel behaves as a single structural unit.

Material properties:

The high-density foam used in TUFF+ SIPs, such as PolyUrethane (PU) or expanded polystyrene (EPS) , offer good compressive strength and insulation properties.

Panel thickness:

Thicker SIPs have higher compressive and bending capacities, as the increased depth provides greater resistance to buckling and bending. TUFF+ House kits can provide higher insulation layer widths of 6″ (150mm) and 8″ (200mm) where required for TRANSVERSE loads, such as upper sub-floors or roofing.

Factory controlled manufacturing:

SIPs are manufactured in a controlled environment, ensuring consistent quality and accurate dimensions, which contributes to their structural integrity.

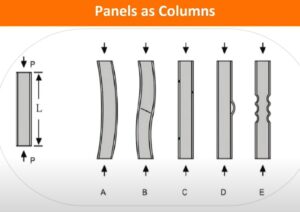

SIPs must maintain structural integrity and TUFF+ SIPs are factory tested to ensure that these types of distortion can not happen under heavy loads, including safety factors:

Panel Size

The largest SIP panel size manufactured to date is 9′ x 24′ (2.7 x 7m). Curved panels are possible although not common and it is often more practical to use stud framing for non-orthogonal geometries.

TRANSVERSE loading on SIP panels

SIPs are subject to two major load types, Axial and Transverse.

Axial (The pressure pressing down onto a column from the top) loading is addressed in the topic above.

SIP Transverse Loadings

(e.g. the weight of a person standing on roof beam)

transverse refers to a direction or plane that is perpendicular to the longitudinal axis or midline.

Transverse load on a wall is for example the lateral wind force.

Transverse floor loading examples are furniture (static load) or people (active load)

Transverse roof loading, is caused by snow, water or construction workers.

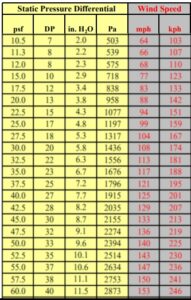

WALL SIP – HURRICANE WIND LATERAL PRESSURE LOADING

Hurricane winds apply significant force to the exterior walls of a house.

These can be significant, as explained below.

TUFF+ SIP houses are designed for storms, hurricanes, typhoons etc.

A wood, steel and concrete frame is NOT required…In fact SIP building shows itself to be stronger in practice:

This is a photo of a hurricane wind demolished housing area:

Look at the wood and cement building around….. all demolished. This is not an isolated example, it is replicated during many high wind events.

FLOOR SIP Transverse loads

ROOF SIP Transverse loads

By increasing the width of a horizontally laid SIP, engineers can significantly improve the structural ability to support loads and resist bending and deflection.

Specifically, the strength of a horizontal SIP (acting as a beam) increases proportionally to the cube of its height.

This strength factor also applies to a vertical SIP such as a wall, where the height of a SIP wall of height H8 carries a load 512 times more than the height of a SIP wall of H1 (if the structure is not subject to bending because of side panel fracture or poor adhesion to the core)

This is the heart of why SIP building is IMMENSELY stronger than stick building.

These loads need to take into account anything that may add force to the roof, including volcanic ash, snow, workers on the roof, heavy rain, the impact of a fallen tree etc.

For roofing these loads need to be taken into account at the same time the specification of the SIP beam will be engineered to cater for the roof span between supports.

The roof span is in turn dependent on the type of spline used.

A SIP spline is a narrow, insulated piece used to connect structural insulated panels (SIPs) together, creating a strong and insulated joint between them.

TUFF+ SIP splines are either mini-SIPs, (S-spline) designed to fit into 50mm recesses in the main SIP panels, or the structurally stronger TUFF+ R-spline which can enable roofing spans in excess of 20 feet (6 meters).

example SIP load chart with mini-SIP spline

Advantages of MgO SIPs

- Strength and Durability:

MgO boards are known for their high strength and durability, exceeding that of plywood, OSB, and particleboard. - Fire Resistance:

MgO boards have excellent fire suppression characteristics, outperforming plywood and other common building materials. - Water and Mold Resistance:

MgO boards are naturally resistant to water damage and mold growth, unlike plywood which can absorb moisture and deteriorate. - Sustainability:

MgO boards are a sustainable option, as they are made from natural, mineral-based materials. - Faster Construction:

SIPs using MgO boards can be assembled faster than traditional stick-built homes, reducing construction time.

- Reduced Waste:

MgO SIPs can help reduce construction waste compared to traditional methods. - Improved Insulation:

MgO SIPs are airtight and insulated, leading to better energy efficiency and reduced heating/cooling costs. - No Harmful Off-Gassing:

Unlike OSB wood composites, which may contain formaldehyde-based glues, MgO boards are free of VOCs, promoting better indoor air quality. - Versatility:

MgO boards can be used for various applications, including fascias, soffits, tile backers, wall and ceiling linings, and underlayment.

MgO board is generally considered stronger and more durable than OSB/plywood, especially in the context of Structural Insulated Panels (SIPs), offering superior fire resistance, water resistance, and longevity.